This is the second of three blog posts confronting the claim that “compromises” must be made when applying energy-efficient technology to ultra-low freezers . . .

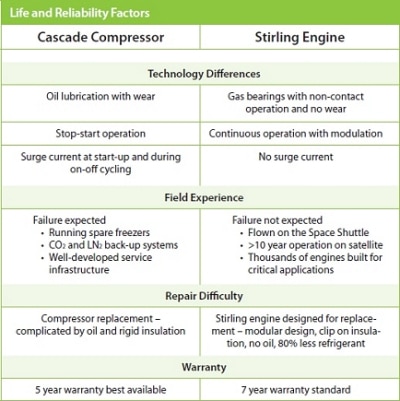

It’s not surprising that an ultra-low freezer technology offering an alternative to decades-old, cascade-compressor technology might create some skepticism when it comes to reliability. And if that alternative consistently consumes less than half the energy of compressor-powered ULTs, as is the case with Stirling freezers, you might expect those defending the status quo to suggest that energy efficiency comes at a price to system reliability. This is simply not true and I would like to address this myth . . .

The First Step to Recovery is Admitting There’s a Problem

It is surprising that anyone would suggest that the state of cascade-compressor freezer reliability even remotely resembles a healthy picture. When an executive of a prominent manufacturer once publically stated, “All freezers fail” he was referring to the disappointing failure rates of cascade-compressor freezers. Many of these manufactures have built high failure rates into their selling narrative so that “redundant capacity” has become a prevailing industry standard. In fact, cascade-compressor systems not only consume enormous amounts of electric power, but that power produces a significant amount of heat that negatively impacts their reliability.

The Stirling Engine: Two Moving Parts in Continuous, Non-Contact Operation

On the other hand, our Stirling cooling engine generates less than half the heat and has only two moving parts – a piston and a displacer. These two moving components are supported on gas bearings enabling non-contact operation and, unlike compressors; there is no wear during normal operation of the engine. The engine requires neither oil nor any other form of lubrication. The Stirling piston operates at a fixed frequency by an integral permanent magnet linear motor. Unlike compressors that operate under stop-start conditions that degrade mechanical reliability, we purposefully designed our engine to run continuously with modulation, so that the damaging effects of current surges are avoided during on-off cycling.

Industry’s Best Standard Warranty

Free-piston Stirling engines of this design have been proven in numerous applications, have flown on the Space Shuttle and continue to cool the instruments on the RHESSI satellite. More than 6,100 Stirling engines have been incorporated into laboratory equipment, including more than 2,450 ULT freezers operating in over 60 research facilities and institutions. The exceptional quality of the Stirling cooling engine provides the foundation of our 7-year standard warranty with all freezers, because we are willing to stand behind the reliability of our product.

The value of having “been around for a long time” in an industry isn’t what it used to be in these times of technological change. In fact, that could be the real compromise in an industry marked by decades-old technology and lackluster reliability performance.