We removed the compressors. You’re welcome.

How we replaced the compressors in our ultra-low freezers with the free-piston Stirling engine — and why that’s a huge benefit for you.

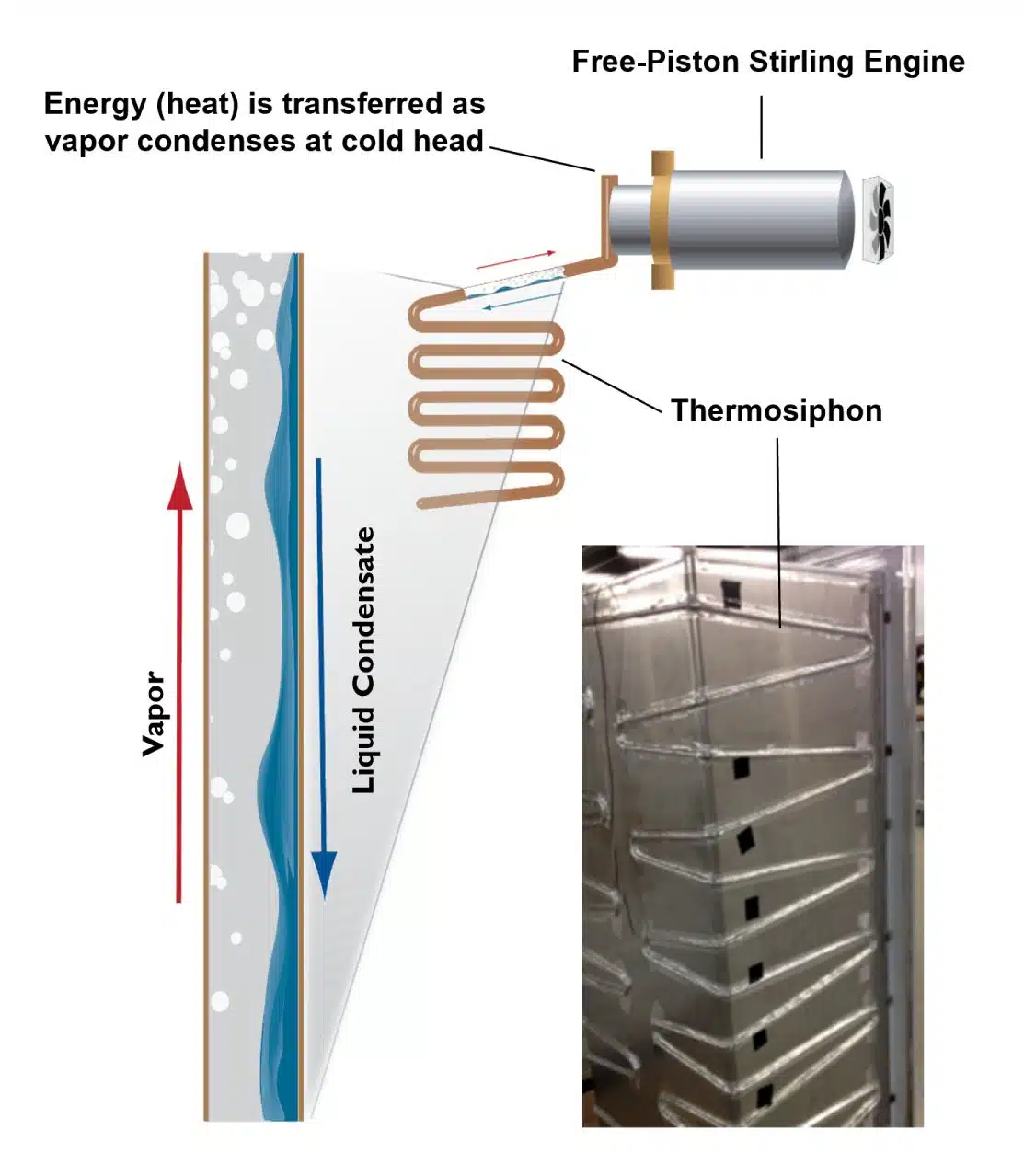

Unlike failure-prone cascade ULT systems, which use two compressors and cooling loops in a cascading arrangement, the simple free-piston Stirling engine design uses a reciprocating piston and displacer, along with a continuous, gravity-driven thermosiphon to cool the cabinet interior.

How does the free-piston

Stirling engine work?

- The advanced linear motor and thermosiphon system design is inherently more efficient and stable, with only two moving parts.

- The two moving parts, the piston and the displacer, expand and compress helium in the engine, absorbing heat from the thermosiphon, keeping the cabinet cold.

- The gravity-fed thermosiphon “hugs” the inner cabinet and is charged with 100 percent natural R170.

- Similar to steam condensing on the lid of a pot of boiling water, R170 refrigerant is condensed to liquid near the “expansion zone” of the Stirling engine and flows down the thermosiphon via gravity. As it absorbs heat from the interior cabinet of the freezer, it turns to gas, rising back up the tube where it is cooled back to a liquid and the process repeats.

How does the Stirling engine revolutionize ULT system reliability?

- The two moving parts never wear because gas bearings eliminate all physical contact (friction) during motion, like a puck on an air hockey table.

- There is no oil to clog up the system or lubrication levels to maintain.

- The system requires virtually no maintenance.

- Continuous modulation controls temperature like cruise control maintains speed in your vehicle. Compressor start/stop cycles would be like controlling your car’s speed by cycling the ignition on and off. These excess mechanical and electrical stress leads to failures and higher electrical usage.

- The thermosiphon is isothermal, driving superior interior temperature uniformity without high pressure or pumps.

The first and best ENERGY STAR®-certified ULT storage solution

At -80°C, Stirling Ultracold ULT freezers use 70–75 percent less energy than standard compressor-based ULT freezers. Our SU780XLE upright model meets the ENERGY STAR certification without using a performance-reducing “eco” mode that trades sample safety for energy rating.

Learn more here.

Premium technology with the lowest cost of ownership

Have you considered what your current ULT freezers may be costing you in energy consumption, maintenance, and building HVAC and floor space? You will see significant savings of 40 percent per year over the freezer’s lifetime when replacing legacy models:

- HVAC costs can be up to 60 percent of a lab’s operating costs. SU780XLE technology can reduce HVAC and electrical infrastructure requirements by >40 percent.

- Larger storage capacity per footprint can save up to 70 percent sample storage cost per square meter/foot of floor space.

- Minimal annual maintenance and extremely low lifetime service costs have been proven by thousands of freezers in service.

Learn more here.

Unparalleled commitment to environmental sustainability

Our facility’s zero waste efforts are not a mere symbol or marketing pitch; it’s a reflection of the core values upon which we were founded. We have always brought sustainability and energy efficiency to the research community because it is the right thing to do for the environment, and our facility waste reduction efforts are an extension of the products we provide. Every ultra-low freezer we manufacture supports climate action goals by using 100 percent natural refrigerants, while also delivering the industry’s lowest energy consumption and smallest operating carbon footprint.

Learn more here.