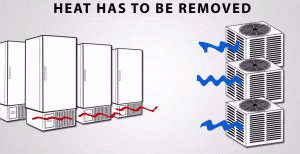

It’s no secret that cascade-compressor, ultra-low freezers require large amounts of energy for cooling. And we know from the first law of thermodynamics that all this energy can’t just be erased, and will be converted into heat. Outside of the cold box, ULTs are essentially heaters! Accordingly, an energy-efficient freezer produces less heat because it uses less energy. That’s why a Stirling Ultracold freezer that uses less than half the energy also rejects less than half the heat.

The Hidden Energy and Cost Benefit – Less Heat Rejection

So, the more ULTs you have running in your research facility, the more heat that must be removed to keep surrounding spaces from becoming uncomfortably hot. What is often overlooked is the HVAC energy cost required to remove that heat. Based on ASHRAE guidelines, removing the amount of heat typically produced by a single cascade ULT can add an HVAC load of about 6 kWh/day. This is not inconsequential if you consider that the power needed to remove the heat from just two cascade freezers is 25% more than the power used by our 27.5 cu. ft. SU780UE freezer! Now consider this energy and cost savings multiplied by 100s of ULTs operated in a research facility. It really adds up.

And don’t forget that hot ambient air around a freezer adversely affects temperature recovery time when the door is opened and that system heat contributes to the disappointing failure rates of compressors.

Impact on New and Upgraded Facilities

For architects and engineers designing new labs or replacing research facility systems, energy-efficient freezers can have a real impact. By accounting for markedly lower energy consumption and heat rejection, laboratory designers can specify lower-capacity, less-expensive power distribution and HVAC systems. This reduces both the initial cost of the project and the long-term operating cost of the facility.